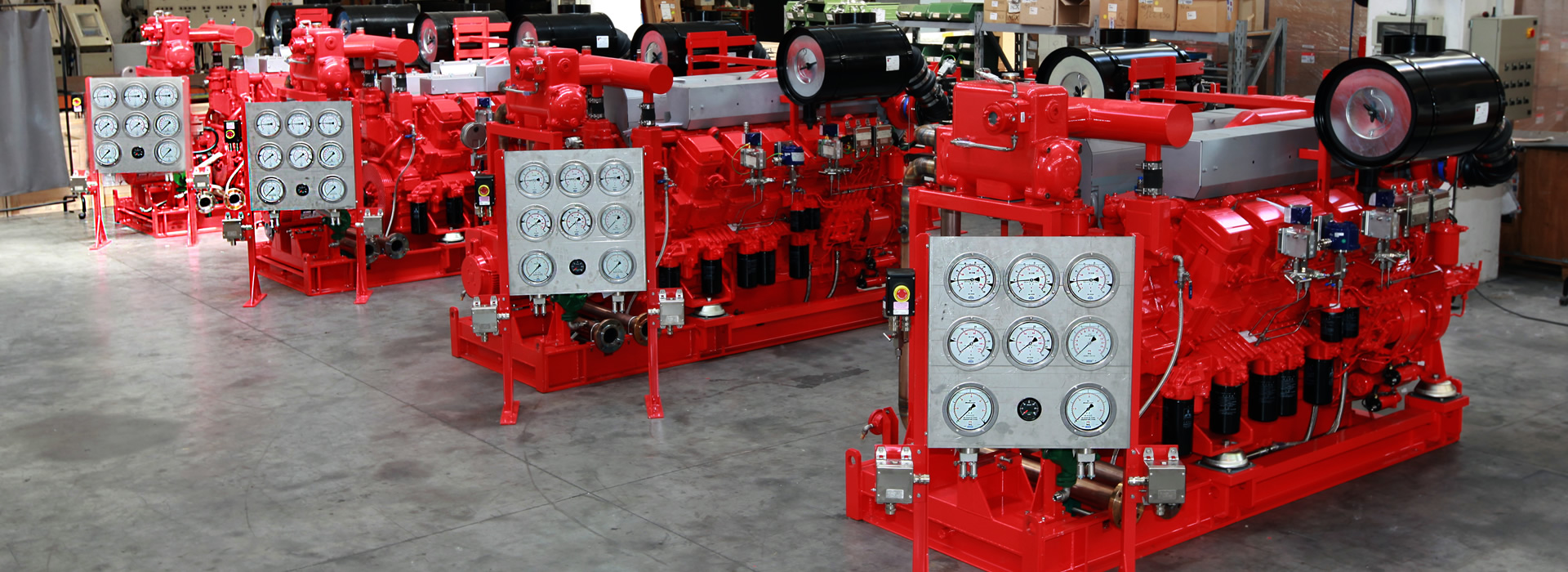

Fire fighting pump packages

CTM has 65 years' experience in the design and manufacture of Diesel Driven Fire Fighting Pump Packages for various applications but mainly Oil & Gas onshore and offshore.LNG terminals, drilling platforms, FPSO, storage terminals, refineries, petrochemical complex amongst others. These packages can meet or exceed customer standards and applicable codes such as UL, FM, NFPA, CE and are built in our ISO 9001 certified manufacturing plant.A Fire Fighting Pump system combine all major equipment and accessories onto a single skid, as an open skid or with enclosure, with:

Prime mover

Diesel engines - Gas fuelled engines available as an option.

Cooling system

Closed circuit by means of vertical core radiator and pusher fan engine driven or, alternatively, through engine fresh water / raw water heat exchanger and relevant cooling water pipework conforming to NFPA20 rule.Different pipework metallurgies are available in relation with the pumped raw water nature (CuNi 90/10; CuNi 70/30; duplex stainless steel F51; super duplex stainless steel F53)

Pump

Horizontal or vertical type, supplied by CTM or by customer

Coupling

Engine and centrifugal pump are coupled by means of elastic coupling with rubber elements and, when required or necessary, cardan shaft. Marine brass antisparking safety protection guard is provided.

Baseplate

Manufactured with painted carbon steel FE 360 b (S235JR) metallurgy, continuously welded according to ASME IX edition. Drip pan with proper drain valve is provided to collect engine leakages. The baseplate is common for prime mover, cooling system, centrifugal pump, starting system, control panel and soundproofing system when required.

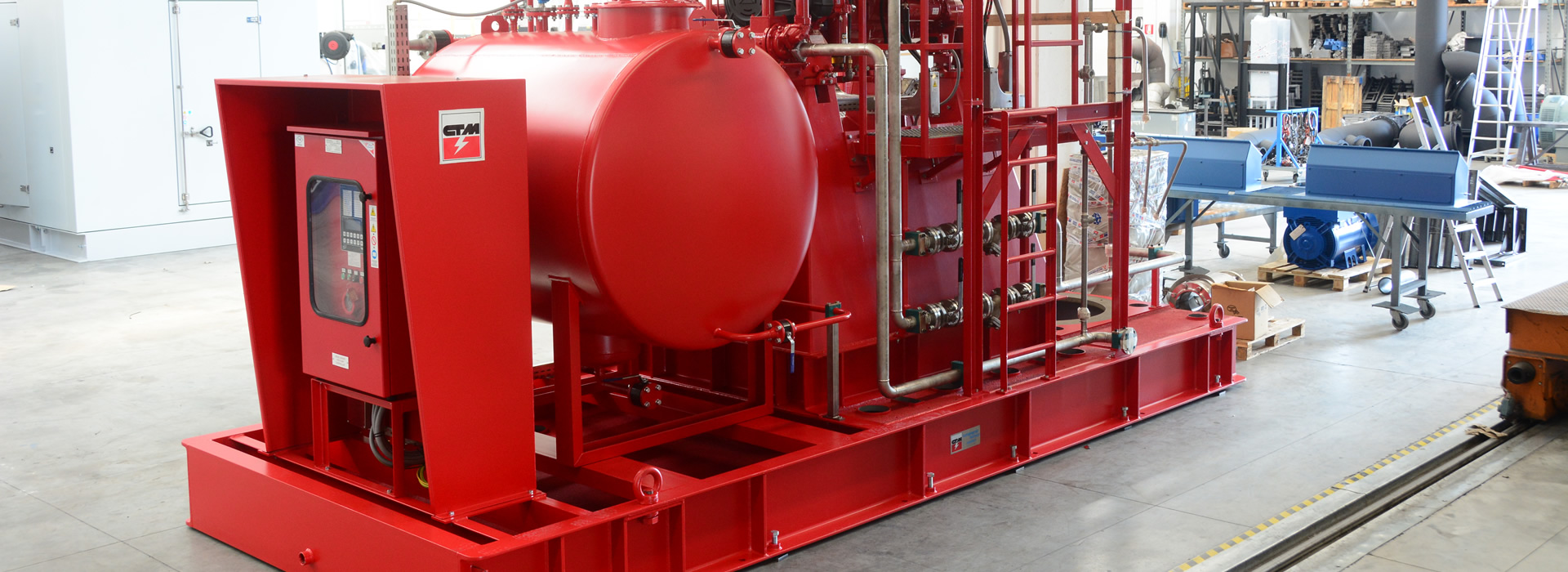

Starting system

Electric: with double set of lead acid or Ni-Cd accumulators 24V.

Pneumatic: with low pressure starter flanged on engine flywheel housing and 16 - 40 bar(g) compressed air receivers

Hydraulic: with high pressure starter flanged on engine flywheel housing and 200 bar(g) oil receivers

Fuel supply system

Cylindrical fuel tank sized according to NFPA 20 rule (5,7 lt/Kw + 5% + 5%), painted carbon steel metallurgy or stainless steel, complete with side level gauge, low fuel level switch, flame arrester, drain valve, fuel supply connection, fuel return connection, overflow connection.

Controller

Carbon steel or stainless steel (on request, manufactured, free standing type or skid mounted. Weather proof enclosure to IP55/ IP65 /NEMA 4X classification suitable for rigorous environmental condition as off-shore oil platforms o petrochemical plants.The controller incorporates the following mains equipment: twin fully automatic battery chargers, weekly start timer, delay start timer, engine heater protection circuit for water, AC supply healthy monitor, battery A healthy monitor, battery B healthy monitor, battery charger A failure monitor, battery charger B failure monitor, auto mode on monitor, pump on demand monitor, cranktimer operating monitor, engine running monitor, engine failed to start monitor, engine low oil pressure monitor (alarm only), engine high water temperature monitor (alarm only), engine overpseed monitor (alarm and shut-down).

Volt free contacts for remote monitoring of engine running, pump on demand, controller off or in manual, fault on engine controller, engine failed to start.

On special request, the following options can be supplied: FM approval, UL listed, air flap circuit, autostop timer module, 7 days chart pressure recorder, adjustable pressure switch for automatic starting

Option available

Soundproofing canopy, with forced ventilation system with electric or hydraulic motor driven fan.

Painting cycles according to project specification and aggressive environments.EEx'd' electric wiring

The Fire Fighting Pump Packages are engineered together with the major pump manufacturers with a dedicated project manager and a highly experienced design team throughout the entire process from initial design to the site commissioning.